CLEANROOMS

A Guide to HVAC Systems Design

A Guide to Cleanroom Design

What is a Cleanroom?

A cleanroom is a room or space in which the level of particulate contamination is controlled within set levels. The construction, temperature, humidity, air flow patterns and pressure are controlled in such a way as to minimise the introduction, generation and retention of particles (such as dust) inside the room. These rooms are used commonly within the scientific research, medical, pharmaceutical and high technology manufacturing industries, where product/sample quality and employee well being are critical.

Cleanroom Classification

Cleanrooms are classified from ISO 1 to ISO 9. These standards are based on the number of particles allowed per unit volume of air within the space. The physical size of a particle is measured in a unit called known as a micron (μm). To put the size of a micron into perspective, a human hair is approximately 75 microns in width. A typical room in a home would contain more than 10,000,0000 particle of 0.5 µm and above, this roughly equates to a class ISO 9 cleanroom.

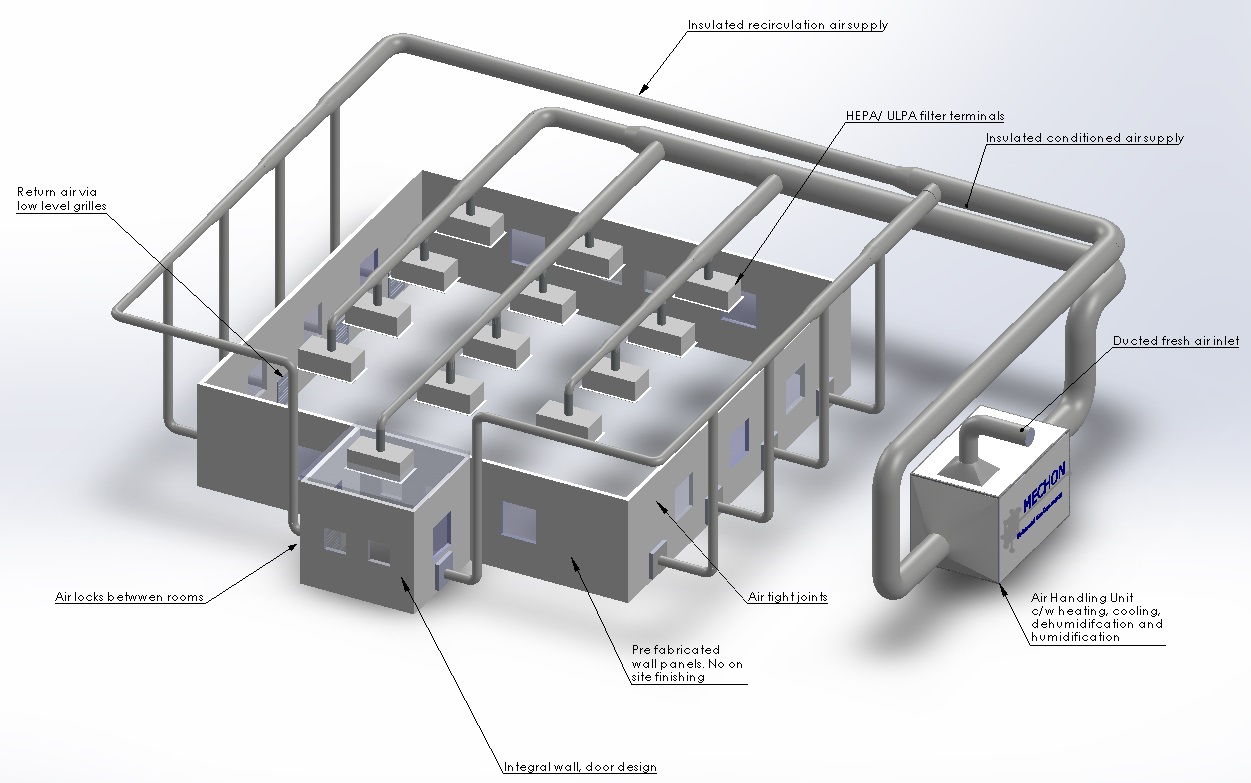

Construction

A cleanroom normally requires a high standard of construction and should be built with walls and ceilings which are airtight and have smooth internal finishes for easy cleaning. Cleanrooms are generally held under a positive pressure, so an airtight construction is critical to avoid overuse of air to maintain positive pressures.

The inner surfaces of a cleanroom should not break up easily and release chips or particles into the surrounding environment. Cleanroom surfaces (especially floors) should be able to withstand strong solvents and acids which may attack surfaces.

Cleanroom structures may be built using conventional building techniques (bricks and motor) however the internal finish should be designed to suit the class of cleanroom. ISO class 8 and 9 cleanrooms may only require epoxy painted walls however this would be dependent on the levels of particles generated by people and processes in the room. Ideally all internal walls should comprise rigid metal or plastic sheets, fixed to a conventional studded wall frame.

An alternative to conventional building techniques is the use of modular wall systems. These systems can be PIR fire rated and insulated to suit internal or external conditions. A wide range of thicknesses are available to meet appropriate ‘U’ values as required by specification. Smooth surfaces and air tight joints reduce building leakage and provide excellent environmental performance.

HVAC System Design

The design of HVAC systems in cleanrooms is different to those for commercial buildings.

What differentiates cleanroom HVAC to conventional systems?

- Increased air supply

- Airflow pattern

- High efficiency filtration

- Room pressurisation

Increased Air Supply Rate

Conventional air-conditioning systems require about 4 to 8 air changes per hour, whereas a cleanroom could require anything between 20 – 90 air changes per hour. The air change rate method of calculation is commonly used in cleanrooms with lower cleanliness requirements (usually ISO 6 to 9), with the air change rate largely based on the level of particles generated by people and processes. Consideration should be made to cleanrooms with higher air change rate requirements, as the HVAC system will use more energy. The designer should provide additional controls capacity that will allow the system to reduce the airflow (using a variable speed drive) to reduce rates when the occupancy rate is low or the room is not in use.

Designers usually calculate airflow rates using the face velocity method when considering cleanrooms of a more stringent classification (ISO 1 to 5). Traditionally, designers have used an air velocity of 0.5 m/s as the standard for cleanroom design, however recent research has shown that velocities as low as 0.35m/s are able to maintain the correct particle count within a room, again dependant on the level of particles generated by people and processes.

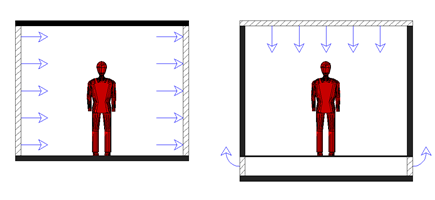

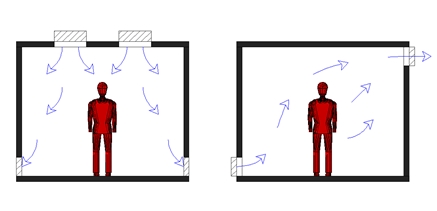

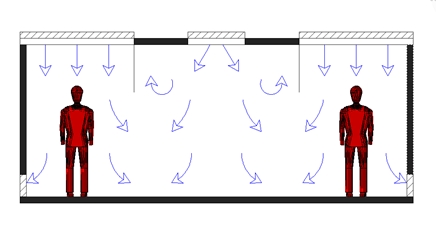

Airflow Pattern

There are three different types of airflow patterns available for cleanrooms designs:

Unidirectional (laminar): the airflow is essentially where the air flows downwards or sideways in an unimpeded path.

Non-unidirectional flow (turbulent flow): where airstreams are other than parallel to one another.

Mixed flow: where airstreams may be parallel in one part of the cleanroom and not in other parts.

Filtration

Cleanrooms utilise high efficiency absolute (HEPA) filters with 99.97% filtration efficiency at 0.3 microns. HEPA stands for High Efficiency Particulate Air. The HEPA filters work on diffusion principle to remove particulate matter. The filters are preferably sited within the terminals of the ducted HVAC system, ensuring maximum cleanliness of air within the room.

Cleanroom Pressurisation

The cleanroom is positively pressurised at a level of between 10 to 25 Pa higher than adjacent areas. This is achieved by supplying more air to the room than is extracted from it.

In clean spaces with several rooms, the most sensitive areas must be pressurised slightly higher than the adjoining rooms. Approximately 5 Pa difference must be achieved from the most to least positive pressure areas. This is to ensure that contaminants are transferred away from the most sensitive areas.

The only exception to using a positive differential pressure is when dealing with specific hazardous materials. Statutory health & safety agencies will require the room to be at a negative pressure.

Mechon’s highly skilled engineers have the ability to address all aspects of cleanroom design, project management. Our technical knowledge and experience allows us to carry out performance, analysis and recommendations for existing cleanroom systems. In some cases, the upgrade of specialist equipment can often rectify performance issues without the need for complete reinstallation to minimise capital costs.

Send Us an Email

How We Work.....

With our in-house team of technical experts, we are able to delivery complex high-technology solutions, within strict cost and time constraints. We are able to consider all aspects of the project to ensure that the operation of processes or supporting services are not affected by the introduction of new systems.

Design

We work with our clients to develop the initial strategic brief. This brief is then evolved into conceptual and final design specification.

Project Management

Our management procedures have evolved with our experience to delivery projects on time and on budget.

Validation

We verify the design and equipment selections of contractor and validate any installations to ensure their correct and safe operation.